Pneumatic Engine Design

RRAGUL KANNA 821116114305 SARUNPANDIYAN 821116114503 EBAZEER 821116114502 KVINOTH 821116114083 in partial fulfillment for the award of the degree of BACHELOR OF ENGINEERING IN MECHANICAL ENGINEERING KINGS COLLEGE OF ENGINEERING ANNA UNIVERSITY CHENNAI APRIL 2019 i BONAFIDE CERTIFICAT Certified that this project DESIGN AND FABRICATION OF PNENUMATIC ENGINE. I would be mostly designing turbine and piston engines.

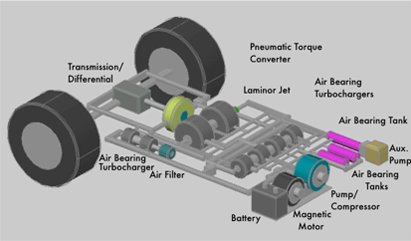

Compressed Air Engine System Layout Download Scientific Diagram

If in a racing application a normal valve spring engine had an upper rpm limit of about 10000 rpm that same engine design when equipped with a Desmodromic valve actuation system would be capable of 15000 rpm and much more power.

Pneumatic engine design. It is also one of the last v10s. For instance there are thousands of types sizes and variations of cylinders and valves from off-the-shelf versions to custom designs. Particles solid Air filter Compressor Air dryer Tank for compressed air Including safety-valve and condensate drain Compressed air network.

A pneumatic wrench delivers 305 Nm of working torque and a max torque of 570 Nm. Common designs of air motors include rotary vane axial piston radial piston gerotor turbine V-type and diaphragm. These designs operate with highest efficiency and longevity from lubricated air.

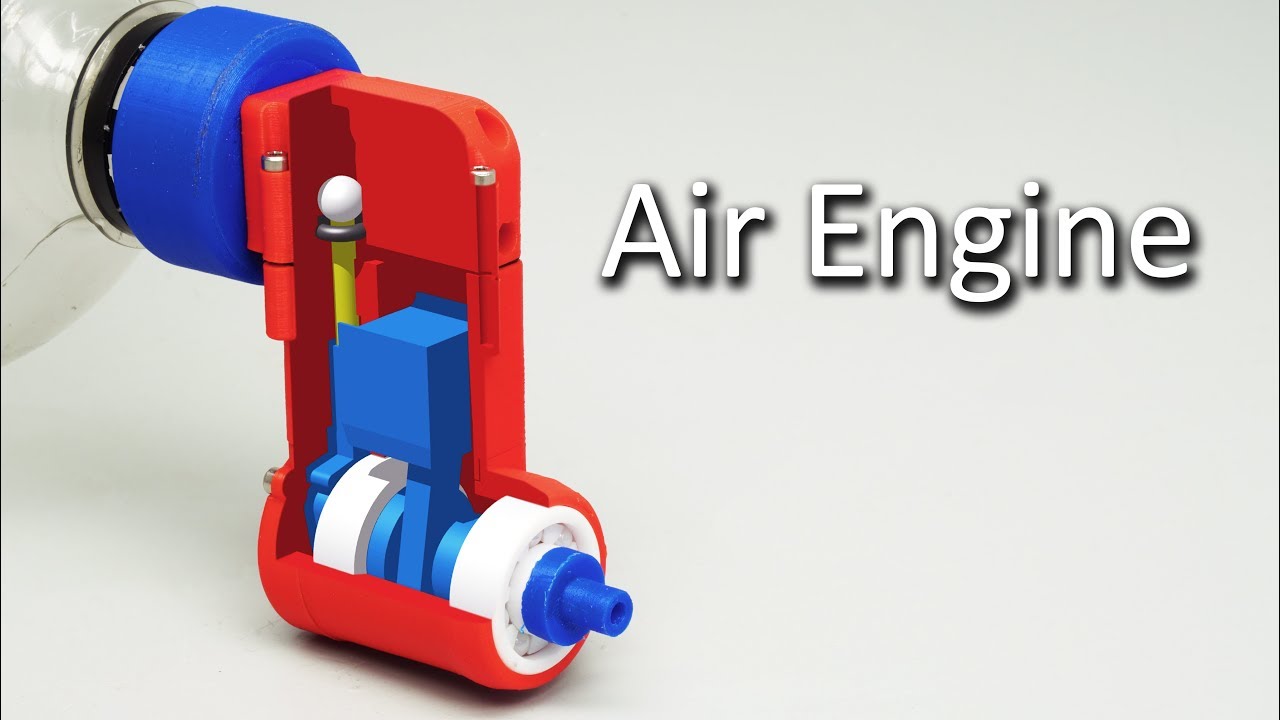

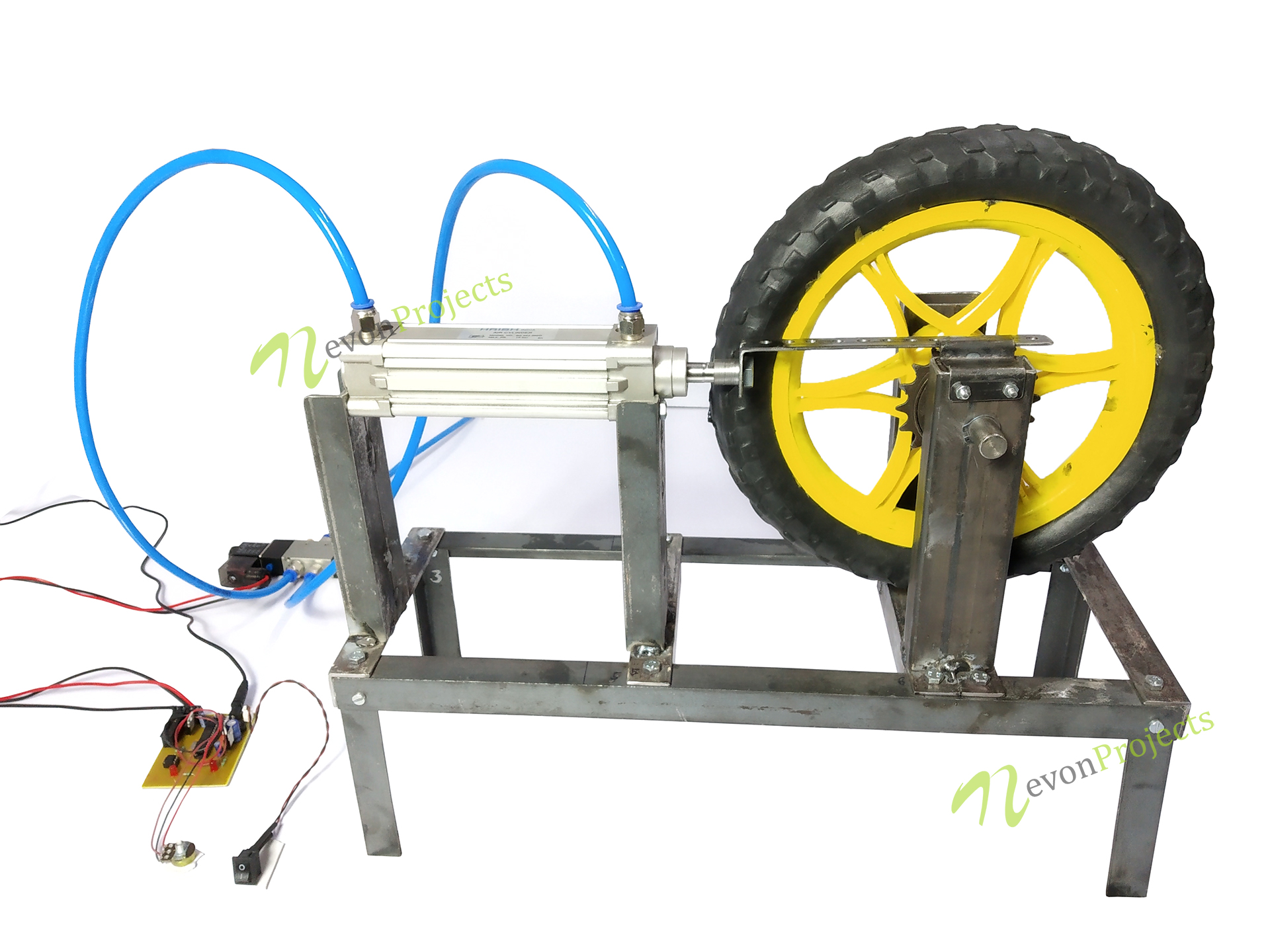

Pneumatic motors ideally utilize either rotary or linear motion for the conversion of compressed air to mechanical work. I was wondering what CAD software free would I be able to use to design and simulate pneumatic engines. A pneumatic motor or compressed air engine is a type of motor which does mechanical work by expanding compressed air.

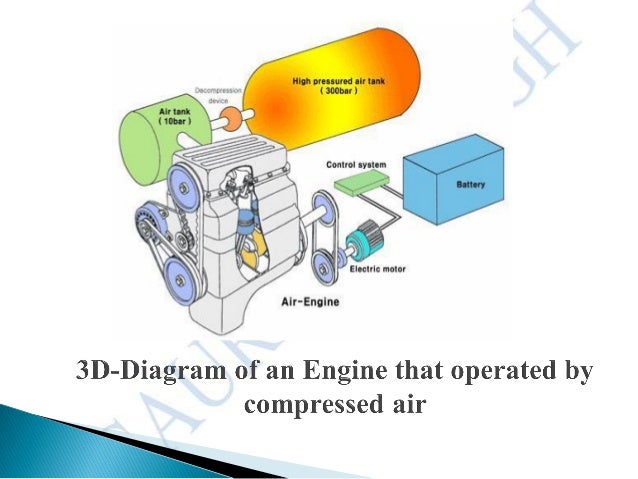

When designing a pneumatic system typically the individual elements are distributed spatially depending on their task. The motor then converts the air power into mechanical power. Once compressed air is transferred into the onboard storage tank it is slowly released to power the pistons.

This should have simple and easy construction. A 4-stroke convention IC engine of 100cc is converted in compressed air engine after modifying camshaft and valve timing. Virtually Frictionless and Leak-Free.

Conventional pneumatic cylinders are successfully used by the millions for factory automation around the world. If playback doesnt begin shortly try restarting. The careful design of valve timings and cam profile allows conversion of conventional 4-stroke IC engine into 2-stroke pneumatic engine.

A pneumatic wrench is a pneumatic tool used to tight and looses the nuts. Activities conducted during project work at icube engineering solutions. It is structure on which all other components will be installed.

A pneumatic impact wrench is a planetary geared torque multiplier or a simple gearbox that is mated to a pneumatic air motor. Rotary vane axial- and radial-piston and gerotor air motors are most commonly used for industrial applications. Pneumatic System Design Considerations Pneumatic systems as a whole can be simple but this simplicity can be deceptive when it comes to selecting components.

For instance given a model of a turbine and an enclosure made of material X and an input air pressure of Y psi estimate the max RPM of the design. A pneumatic air engine is a type of engine which does mechanical work by expanding compressed air. However a recent market study has shown that there is a niche for a model pneumatic engine.

That power is then transferred to the wheels and becomes the source of power for the Engine. The cam needs to be manufactured with care and assembled with correct relative positions. The crankcase has a vent that causes only small compression of the air.

There are many styles of pneumatic actuators. Pneumatic Motor Design Testing - YouTube. A pneumatic motor compressed air engine is a motor that achieves mechanical work thru the expansion of compressed air.

Although they are spatially separated they are still connected systematically. The pneumatic engine can be simply done by modification of the design of the classic two-stroke engine. Design and analysis of camshaft and valve of pneumatic engine of two wheeler Group member.

Pneumatic engine generally converts compressed air energy to mechanical work either into linear motion or rotary motion. Design elements - Pneumatic pumps and motors The vector stencils library Pneumatic pumps and motors contains 39 symbols of pneumatic pumps motors and pump-motors for designing the engineering drawings of pneumatic circuits. DESIGN AND FABRICATION OF PNEUMATIC ENGINE A PROJECT REPORT Submitted By.

Abhi Patel 110250119021 Umang Patel 110250119033. Its from a V10 engine making in the region of 850hp with a rpm limit of approx 15000rpm. ENGINE SPECIFICATION Conventional engine is 4-stroke IC engine without any.

In order to address this opportunity your team leader has asked each of his employees to design and manufacture a working model of a pneumatic piston engine and present their final designs at a review meeting in 14 weeks. It runs pneumatic valve train has four valves per cylinder barrel throttles in-cam oiling valve axis angled in both planes bucket tappets and cam cover coolant distribution. Diaphragm cylinders rodless cylinders telescoping cylinders through-rod cylinders etc.

Write Clearly and Concisely Grammarly. Pneumatic actuators come in many designs and sizesand include a variety of mounting methods internal features and options to provide a robust solution in industrial environments Table 2. The engine does not require the inlet port delivering the air to the crankcase.

Abstract Introduction Characteristic Main component Future plan Index.

File Magnetic Air Car Engine Concept Design Png Wikimedia Commons

Gringoloco S Super Efficient 2 Stage Reciprocating Engine

Pneumatic Engine Project Robert Arcella

Pneumatic Engine Meetkumar Patel

Hybrid Pneumatic Engine Institute For Dynamic Systems And Control Eth Zurich

Schematic Diagram Of An Air Hybrid Engine With An Air Starter Download Scientific Diagram

Pneumatic Engine Design Phase Youtube

Compressed Air Engine A Bridge For Sustainable Development Scialert Responsive Version

Compressed Air Engine V3 Youtube

What Are The Different Types Of Air Motors

Compressed Air Engine System Layout Download Scientific Diagram

Simple Pneumatic Engine 3d Cad Model Library Grabcad

Pneumatic Engine Project Robert Arcella

0 Response to "Pneumatic Engine Design"

Post a Comment